Regulators & Cylinders

Gas Handling Equipment

Backed by our wide distribution channels, we supply a broad gamut of gas handling equipment that ensure safe and proper handling of cylinder gases. Each equipment offered by us is thoroughly tested at manufacturer’s site and further, is inspected by our quality supervisors assuring trouble-free service. Available in variety of industry specific configurations, these are widely used across cement, chemical , medical, food, metal etc.,industries. The array of gas handling equipment offered by us are:

Pressure Gauges

Pressure Gauges

We also provide dial type digital pressure gauges in various sizes and ranges. Sourced from trusted vendors across the country, these are calibrated with master gauges as well as are equipped with traceable NPL. These are widely used across industries like chemicals & fertilizers plants, refineries, thermal power stations etc. The pressure gauges can be availed at best industry prices.

Features:

Gas Cylinder Manifolds

Gas Cylinder Manifolds

Why a Gas Distribution System?

If you think about it, most of the gases are toxic, flammable, corrosive, or often a combination of these. Other gases constitute a different hazard-such as asphyxiation, anesthesia or, simply, pressure. For some customer installations, a simple pressure regulator or control valve will not suffice, for example:

Gas Accessories

Gas Accessories

Supported by wide distribution channel, we offer wide range of industrial gas accessories such as fine control needle valves, S.S. 316 gas sampling valves, flowmeters, tubings, ampules breakers, fittings, couplings, etc. that are procured from reliable vendors. The manufacturers make sure that these are manufactured from quality iron, aluminum, steel, brass castings and forgings as well as conform to the ISO standards.

Features:

Gas Mixing Systems and Gas Blending Systems

Gas Mixing Systems and Gas Blending Systems

The Gas blending system can mix and blend two or more gases with each other at a predefined ratio. It can be used for blending or to dilute gases to generate precise calibration gas standards, production gas mixtures or to create gaseous atmosphere. The gases can be mixed in a ratio of 1:1 upto 1: 1000.

The system automatically dilutes high concentration certified gas cylinder to a wide range of of concentrations from high percentage to low parts per million.

The system is operated by controls set at front panel. After entering required concentration, the system automatically mixes gases connected to the ports to generate required mixture.

Gas Mixing System

The gas mixer precisely dilutes and blends high concentration certified gas cylinders to generate precise gas calibration standards, create gaseous atmospheres, or produce gas mixes for analytical research and process gas mixture purpose.

The mixer can produce complex mixes containing upto seven individual gases in a balance gas. The mixer produces gases from a percentage level to parts per million level for single or multipoint calibration.

The mixer consists of control instrumentation and mixing zone. Commands are entered from front panel. Optional RS232 control with computer controlled command mode is also available.

Features:

Specifications:

Accuracy: From 10 to 100% of full scale: ? 1% for concentration and flow and repeatability

Gas Changeover Module

Gas Changeover Module

This unique equipment is designed for application where many gas lines are to be cross linked to be cross linked to an instrument & carrier gas is changed from one to another frequently.

This equipment is suitable for varying pressures, with all wetted parts in S.S.304 / 316, is available ready for a wall mounted installation

High Pressure Cylinder Changeover Manifold

High Pressure Cylinder Changeover Manifold

These are designed for high pressure application and to changeover the gas supply from a near empty cylinder to full cylinder quickly.

The standard version is for two cylinders, is made of S.S.316 and is compatible to most of the gases and flexible tail pipes.

Manifold for more number of cylinder are also available

Pressure Gauges

Pressure Gauges

We also provide dial type digital pressure gauges in various sizes and ranges. Sourced from trusted vendors across the country, these are calibrated with master gauges as well as are equipped with traceable NPL. These are widely used across industries like chemicals & fertilizers plants, refineries, thermal power stations etc. The pressure gauges can be availed at best industry prices.

Features:

- Diaphragm operated

- Measure positive, negative, or differential pressure

- Cast aluminum black IP – 55 weather proof case

- Low maintenance cost

- Brass / SS Movement

- Direct, Surface & Panel mounting

Gas Cylinder Manifolds

Gas Cylinder Manifolds

Why a Gas Distribution System?

If you think about it, most of the gases are toxic, flammable, corrosive, or often a combination of these. Other gases constitute a different hazard-such as asphyxiation, anesthesia or, simply, pressure. For some customer installations, a simple pressure regulator or control valve will not suffice, for example:

- Where the gas, for physical considerations of space or location, must be stored in an area remote from point of use.

- Where two or more cylinders are coupled together for high flow-rates.

- Where a regular purge cycle is required between gas uses or at cylinder change-over.

- Where safety considerations with a toxic or flammable gas require that equipment and/or pipelines containing that gas should be totally isolated from the working environment.

- Where gas flow, pressure or temperature requirements are such that a very sophisticated means of gas control is required, especially in bulk gas installations.

- In this there is clearly a need for a specialist designed Gas Distribution System.

Gas Accessories

Gas Accessories

Supported by wide distribution channel, we offer wide range of industrial gas accessories such as fine control needle valves, S.S. 316 gas sampling valves, flowmeters, tubings, ampules breakers, fittings, couplings, etc. that are procured from reliable vendors. The manufacturers make sure that these are manufactured from quality iron, aluminum, steel, brass castings and forgings as well as conform to the ISO standards.

Features:

- Manufactured using high quality stainless steel or brass

- Used across industries like metal, medical, chemical, food, pharma etc.

- Wide range of equipment such as valves, flowmeters, tubings etc.

- Variety of valves like flanged, socket weld, screwed etc., are offered

- Fittings include PVC fittings, polypropylene fittings, steel fittings, malleable iron fittings

- Size: 15 mm to 250 mm

Gas Mixing Systems and Gas Blending Systems

Gas Mixing Systems and Gas Blending Systems

The Gas blending system can mix and blend two or more gases with each other at a predefined ratio. It can be used for blending or to dilute gases to generate precise calibration gas standards, production gas mixtures or to create gaseous atmosphere. The gases can be mixed in a ratio of 1:1 upto 1: 1000.

The system automatically dilutes high concentration certified gas cylinder to a wide range of of concentrations from high percentage to low parts per million.

The system is operated by controls set at front panel. After entering required concentration, the system automatically mixes gases connected to the ports to generate required mixture.

Gas Mixing System

The gas mixer precisely dilutes and blends high concentration certified gas cylinders to generate precise gas calibration standards, create gaseous atmospheres, or produce gas mixes for analytical research and process gas mixture purpose.

The mixer can produce complex mixes containing upto seven individual gases in a balance gas. The mixer produces gases from a percentage level to parts per million level for single or multipoint calibration.

The mixer consists of control instrumentation and mixing zone. Commands are entered from front panel. Optional RS232 control with computer controlled command mode is also available.

Features:

- Reduced cost of Gas Standards: Calibration gases is a costly affair. The mixer reduces / stops costly expense of calibration gases needed for calibration of instruments. Also reduced inventory of gas cylinders due to broad range of dilution ratios. It enhances profitability in process industries due to eliminating costly process gas mixtures. The mixer can be used for online gas mixing.

- Wide Dilution Ratio: Broad range of dilution ratios (1:1 upto 10000:1) allows user to significantly reduce the number of gas cylinders needed to perform compliance tests.

- State of the Art Software: Automatic calculation of dilution and span gas flows based on the concentration commanded by the user eliminates the need for manual computation allows rapid transition from point to point and scale to scale.

- The mass flow controllers are calibrated to using a NIST traceable primary standard.

Specifications:

Accuracy: From 10 to 100% of full scale: ? 1% for concentration and flow and repeatability

- Inlet Port ¼” OD swagelok

- Outlet Ports ¼” OD swagelok

- Operating pressure at inlets: 25 psig

- Tubing Electro polished SS316

- MFC SS316

- Seals Viton (Optional – Karlez, Buna –N, Neoprene)

- Operating Temperature 0 – 500 C

- Data Output / Input RS232 serial data

Gas Changeover Module

Gas Changeover Module

This unique equipment is designed for application where many gas lines are to be cross linked to be cross linked to an instrument & carrier gas is changed from one to another frequently.

This equipment is suitable for varying pressures, with all wetted parts in S.S.304 / 316, is available ready for a wall mounted installation

High Pressure Cylinder Changeover Manifold

High Pressure Cylinder Changeover Manifold

These are designed for high pressure application and to changeover the gas supply from a near empty cylinder to full cylinder quickly.

The standard version is for two cylinders, is made of S.S.316 and is compatible to most of the gases and flexible tail pipes.

Manifold for more number of cylinder are also available

Industrial Gas Regulators

We Supply Gas Regulators which are made up of Stainless steel and Brass for gases such as :-

|

Features:

Features:

- Made up of top grade stainless steel and brass

- Widely used for gas cutting or welding purpose

- Have built in safety relief valve and flow control needle valve at the outlet

- Also used as adjustable pressure regulator for LPG/ Natural Gas

- Suitable for high pressure applications as well

- Completely corrosion resistant

High Pressure Gas Regulator

High Pressure Gas Regulator

We supply a comprehensive range of diffusion resistant gas pressure regulators that are used to reduce high-pressure gas in a cylinder or process line to a lower, usable level as it passes to another piece of equipment.

The regulators also maintain pressure within a gas delivery system. Sourced from well reckoned manufacturers, these are designed in confirmation to international quality standards.

These can be availed at most reasonable prices.

Standard Specifications :

|

Features:

- Used to control delivery pressure

- Reduce high-pressure gas in a cylinder

- Ensure 100% diffusion resistance

- Handle safely a high purity, calibration, toxic and corrosive gases

- Made of stainless steel and brass

- Maintain the integrity of gases

Gas Regulator Working

A gas regulator or a pressure regulator or simply regulator is a device that automatically cuts off the flow of gas at a certain pressure. Widely used in gas plants or gas systems, regulators are meant to reduce the pressure from a high pressure source to a safe working pressure for use. It is a very essential equipment to bring about a positive control of the pressure in a gas stream. A safety tool, it reduces high-pressure gas in a cylinder or process line to a lower level that is usable and maintain pressure in a gas delivery system. In other words, regulators are used to control delivery pressure only. Regulators are suited to most industrial grades of gases and fluids up to 99.99% purity (which includes helium, hydrogen, acetylene, argon, oxygen and CO2).

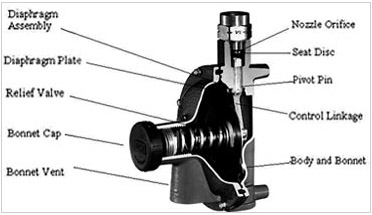

Basic Operating Components

In gas pressure regulators, there are three basic operating components, which work together to obtain pressure reduction. They are as follows:

Parts of a Typical Regulator

Types of Regulators

There are four main types of gas pressure regulators:

Regulators: Design Types

Regulators are generally classified into 3 design types types:

On the basis of the above design types, gas regulators can be classified as follows:

Basic Operating Components

In gas pressure regulators, there are three basic operating components, which work together to obtain pressure reduction. They are as follows:

- A loading mechanism: The setting of the regulator delivery pressure depends on loading mechanisms. The loading mechanism usually make use of a spring and with turning of the regulator's hand knob, the spring is compressed. Force is applied on the spring and transferred to both the sensing element and the control element to achieve the outlet pressure.

- A sensing element: Sensing elements imply the components which sense the force put on the spring, which in turn set the delivery pressure. A diaphragm, either constructed of elastomers or metal, is usually as the sensing element and it is this element which communicates this change in force to the control element.

- A control element: The control element in gas regulator is the valve that leads to the reduction of inlet pressure to outlet pressure. With the turning of the gas regulator's hand knob, there is compression of the loading mechanism, which displaces the sensing element (diaphragm) which in turn pushes on the control element, causing it to move away from the regulator's seat, and provide the flow and pressure required.

Parts of a Typical Regulator

Types of Regulators

There are four main types of gas pressure regulators:

- Line Gas Pressure Regulators:Line regulators are point-of-use gas pressure regulators. They serve low-pressure pipelines, used with high-pressure cylinder regulators. The line pressure regulators limit the inlet pressure from 250 to 400 psig.

- General-purpose Gas Pressure Regulators:It is a common type of gas pressure regulators, specially designed for economy and longevity, and preferred for noncorrosive general plant, pilot plant, and maintenance shop applications.

- High-purity Gas Pressure Regulators: They provide diffusion, resistance, and easy cleanup. inboard diffusion eliminated by metal diaphragms and high-purity seats and seals. Special service gas pressure regulators: Specialized regulators are specifically constructed for specialized applications like high-pressure, ultra high-pressure, oxygen, acetylene and fluorine service, and corrosion service.

Regulators: Design Types

Regulators are generally classified into 3 design types types:

- With no gauge: They are economical general purpose regulators and here monitoring of the gas supply and outlet pressure is not needed.

- One gauge: These regulators show the inlet pressure only but can be supplied to show the outlet pressure instead.

- 2 gauges: This model shows accurate pressure reading of both inlet and outlet pressures and is the most popular design used today.

On the basis of the above design types, gas regulators can be classified as follows:

- Single-stage Regulators: : They give good pressure and flow characteristics. Suitable for short run analytical work, engineering and industrial applications, these regulators are available in a range of inlet and outlet pressures (up to 6000 psi) to suit most gases.

- Two-stage Regulators: : Also referred to as multi-stage regulators, they have all the features of single-stage regulators. Besides that with the two gas reduction chambers, they provide additional safety and specific control over the complete inlet pressure range. Multi-stage regulators are capable of working with cylinder pressures up to 300 Bar with safety and precision control. They provide the ultimate answer to gas pressure requirements, and can be found in many diverse applications including gas plants, life support systems, laboratory supply systems, food and drink processing, and high tech manufacturing.

- Product description

- Available sizes

- Maximum inlet and outlet pressures (operating and emergency)

- Flow capacity • End connection styles

- Outlet pressure ranges

- Construction materials

- Temperature capabilities

- Accuracy

- Pressure registration (internal or external)

Buying Tips

With the increasing number of different types of regulators available and the endless lists of specifications in manufacturer's literature, there is a problem in selecting the right regulator for the right purpose. The Natural Gas Regulators Application Guide and the Industrial Regulators Application Guide is designed to help you in making a right choice for a regulator that fits your application's specific needs. The following specifications can be evaluated:

Industrial Gas Cylinder

Seamless Steel Cylinders for Industrial Gases are widely used in:

Seamless Steel Cylinders for Industrial Gases are widely used in:

- welding

- flame or plasma cutting

- machinery engineering

- many other areas

Our company supplies variety products from (0.075m3) one meter cubic, to (24m3) twenty four cubic meter.

Cryogenic Gas Cylinder

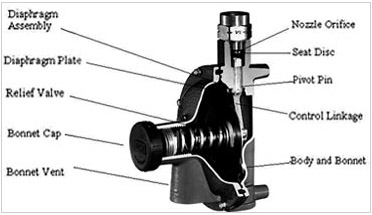

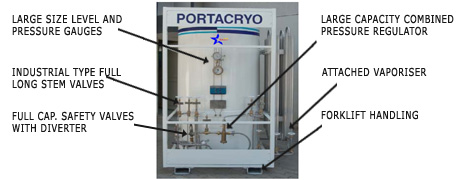

Portacryo:

Portacryo:

- Portable Cryogenic Tank

- Less Than 1000 Lit.

- Pressure Rating 19, 34 Kg/cm2

Design & Constructional features:

- Incorporates all the features of customer station combined with benefits of liquid cylinder

- Handling by Forklift, Mobile crane, Chain pulley block, Shop crane (EOT)

- Can be filled by Transport tank or taken to ASU/Bulk liquid station for filling LIN/LOX

Portacryo - Design Features:

- Design Code AD2000

- Also Available With ASME/U Stamp

- Net Capacity 848 Liters

- Ner < 1% For LOX At STP

- Can be Transported with Lar Full

- Also Available in 1500/2000 Liters

- No Foundation Required

Design Features:

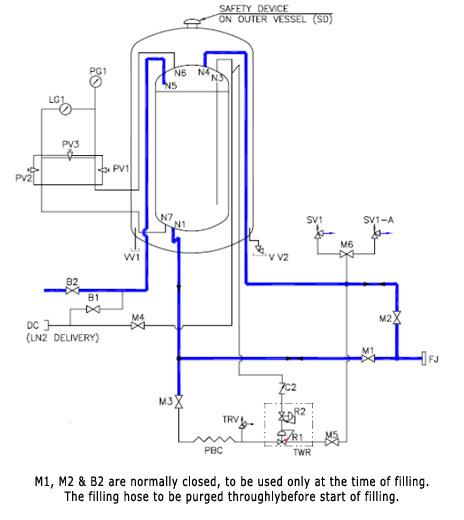

Portacryo - Operation:

Portacryo - Operation:

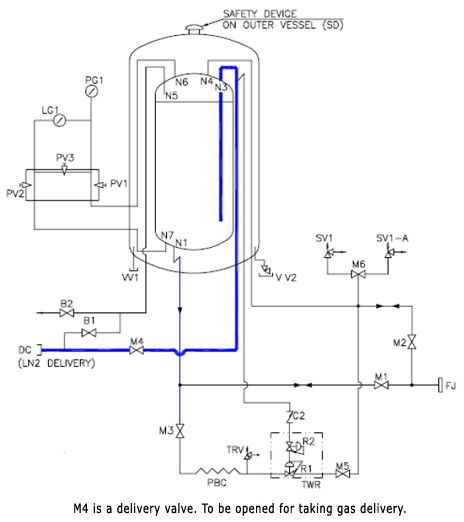

- Liquid Filling

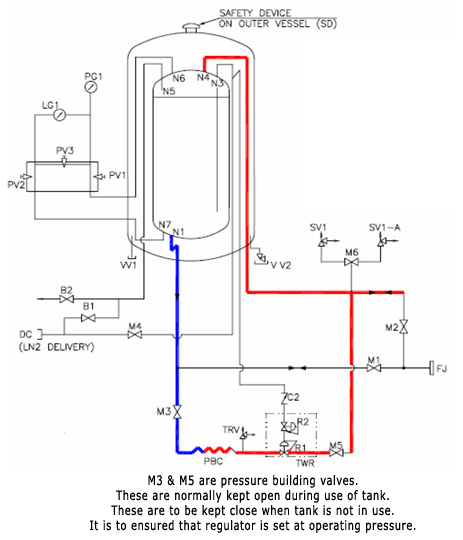

- Pressure Building

- Liquid Delivery

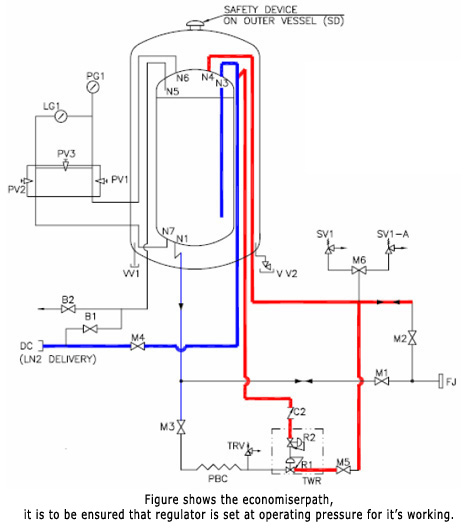

- Liquid Delivery With Economiser

Liquid Filling:

Pressure Building:

Delivery Of Liquid:

Delivery Of Liquid With Economiser:

Product Images:

© 2010 Star Special Air Gases Private Limited - All Rights Reserved.